Thanks for the compliments.

The bamboo in both the corner and what my buddy calls an elevator, was cut and at least cured one month. It is mostly just Oldham's Bamboo that was cut from a deserted property along I-95 in Ft Laud. Some of the poles across the top is Black Bamboo. Some of the other varieties I don't have the name of.

I cemented the poles using hydraulic cement and made sure there was cement in the bottom of the holes so it cannot rot from the bottom up. This may not be the best way, so we'll see. The cross poles were secured using galvanized threaded rod that were set with wide galvy fender washers, lock washers, and regular nuts (not lock nuts or stainless) on both ends. I used threaded rod and cut off the excess. This negated the differences of the sized bamboo. Threaded rod by the foot was half the cost of lag bolts.

The bamboo poles across the top of the bamboo pergola were simply attached with a 1" decking screws and finish washesr. Same as the cora-plastic roofing material in the corner.. I used quartered bamboo (hand cut w/circular saw) across the corner structure as rafters.

The main pergola is all PT with hurricane straps. It is rock solid and also has sprinkler lines fed up to it. I'll do the same in the future to the bamboo "elevator" but not the corner "dry zone".

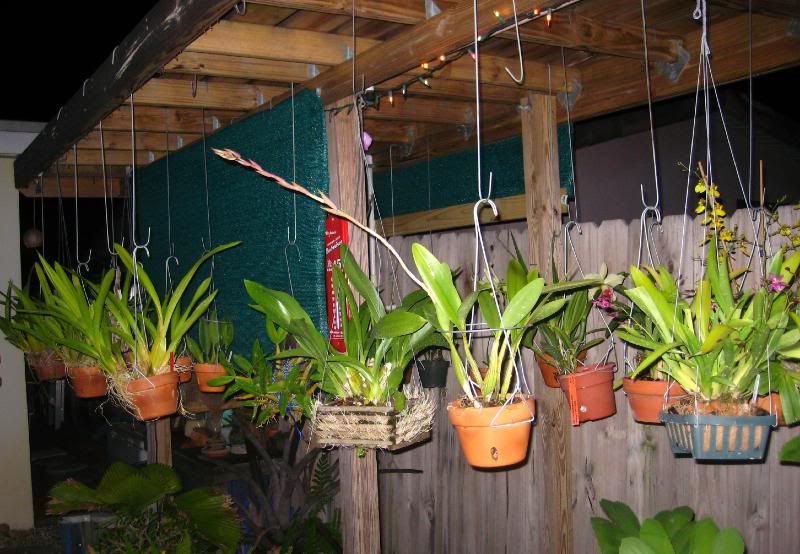

If I would do anything different, I would use screening cloth across the main pergola, but after I build my next area (covered circular white plastic roof with no rain thru), the other areas will be just display areas. Think go big, or go home.

It's just a grow in process since I started growing cids `bout 3 yrs ago.

BTW, I'm looking at doing lights inside my Florida Room, just gotta get the wifey's OK [yeah-right]

I love what you've done with the bamboo. Would you be willing to share some details of construction? I have several long pieces of the stuff just lying on the side of my house. It has dried and I may have waited to long to use it. Was your bamboo dry when you built your structure and how did you make the cuts, drill holes, and attach bolts without splitting. Any framing and connection details you could furnish would be greatly appreciated.

I love what you've done with the bamboo. Would you be willing to share some details of construction? I have several long pieces of the stuff just lying on the side of my house. It has dried and I may have waited to long to use it. Was your bamboo dry when you built your structure and how did you make the cuts, drill holes, and attach bolts without splitting. Any framing and connection details you could furnish would be greatly appreciated.  Thank you.

Thank you.

Linear Mode

Linear Mode